Imagine a world in which precision and efficiency go hand in hand, seamlessly weaving collectively to create perfect motion control. Enter the area of Rotary Stage Motion Systems – the unsung heroes behind the curtain, orchestrating elaborate movements with utmost accuracy. Join us on a journey to explore how these revolutionary structures are revolutionizing industries and maximizing overall performance like never earlier than!

What is a Rotary Stage Motion System?

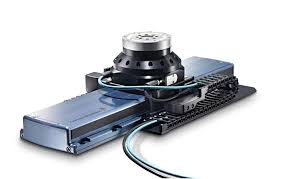

At its core, a Rotary Stage Motion System is a sophisticated mechanism designed to precisely rotate an item round a hard and fast axis. Think of it because the silent powerhouse that provides finesse and control to actions in numerous industries. These systems are prepared with high-precision components like cars and encoders, making an allowance for accurate positioning and seamless operation.

By harnessing the energy of rotational movement, Rotary Stage Motion Systems play a critical function in responsibilities requiring tricky angular changes or non-stop rotation. Whether it is in manufacturing processes, clinical research, or even amusement venues, those structures provide extraordinary flexibility and reliability.

With adjustable velocity settings and programmable features, Rotary Stages can cater to numerous applications that demand meticulous movement manipulate. From testing system calibration to automatic meeting lines, the versatility of those systems is aware of no bounds.

Benefits of Using a Rotary Stage Motion System

When it comes to precision and performance in movement manage, a rotary level movement device gives sizable advantages. These systems are designed to offer accurate angular positioning, enabling smooth and managed rotation for numerous programs. By incorporating a rotary level into your setup, you could gain particular movements with high repeatability.

One of the important thing benefits of using a rotary level motion system is its versatility. Whether you want non-stop rotation or specific incremental steps, these structures can accommodate a huge range of rotational necessities. This flexibility makes them ideal for obligations inclusive of alignment, inspection, testing, and more.

Furthermore, rotary tiers are recognised for his or her compact layout and strong production. They can without problems combine into current gadget setups with out taking on an awful lot space whilst maintaining balance during operation. This aggregate of durability and compactness makes them suitable for demanding commercial environments wherein reliability is paramount.

Leveraging a rotary degree motion system to your workflow can result in stepped forward accuracy, increased productiveness, and enhanced performance across various industries.

Types of Rotary Stages

Rotary ranges are available in various sorts, every designed to cater to precise motion manipulate wishes. One not unusual kind is the bug power rotary degree, acknowledged for its excessive torque skills and clean operation. This type is right for applications requiring particular positioning and stability.

Another famous choice is the direct-power rotary level, which gives speedy reaction instances and superb accuracy due to its direct coupling with the motor. It is often utilized in dynamic applications where velocity and precision are crucial.

Air-bearing rotary ranges make use of a cushion of air to obtain frictionless motion, making them appropriate for ultra-high precision obligations wherein even the slightest disturbance can impact outcomes. These tiers are prized for his or her relatively smooth motion and minimal wear through the years.

Piezoelectric-pushed rotary levels offer sub-nanometer decision through leveraging piezoelectric actuators that respond rapidly to voltage modifications. They excel in nanotechnology studies and other fields disturbing intense precision at the microscale level.

Factors to Consider When Choosing a Rotary Stage Motion System

When choosing a rotary degree motion system, it’s crucial to don’t forget the specified stage of precision to your software. Different structures provide various stages of accuracy, so knowledge your unique wishes is prime.

Another element to maintain in mind is the load capacity of the rotary degree. Ensure that the gadget you pick out can assist the load of your equipment without compromising overall performance.

Consider the rate and acceleration competencies of the rotary stage motion system. Depending on your project requirements, you may want a gadget which could circulate speedy and easily.

Compatibility with different additives for your setup is essential. Make sure that the rotary degree integrates seamlessly with any current gadget or software you are the use of.

Don’t forget about about finances constraints. Evaluate the fee-effectiveness of different alternatives even as balancing overall performance and nice to find a answer that meets each your technical necessities and economic boundaries.

Precision and Accuracy in Movement Control

In the world of precision engineering, manipulate over movement is paramount. A rotary stage motion device gives unprecedented accuracy in positioning and controlling rotational actions with utmost precision.

The ability to exactly modify angles down to minute levels allows for tricky and complex operations in numerous industries together with manufacturing, optics, and research.

With advanced technology like stepper automobiles and encoders incorporated into rotary degrees, users can attain specific positioning repeatability making sure constant overall performance through the years.

This level of accuracy opens up a myriad of possibilities for applications requiring meticulous manage over angular moves, from aligning optical additives to accomplishing particular measurements in research settings.

Precision and accuracy in movement control aren’t just applicable however vital on the subject of accomplishing extremely good effects in duties that demand exactitude at each flip.

Applications of Rotary Stage Motion Systems

Rotary level movement systems are tremendously versatile gear that discover software in a huge range of industries. In the sphere of manufacturing, rotary levels play a essential function in precision cutting and shaping techniques, making an allowance for difficult designs to be done with unprecedented accuracy.

In the area of clinical studies, rotary tiers are applied for positioning samples underneath microscopes or aligning optics in experimental setups. Their ability to precisely manage movement allows researchers to behavior experiments with utmost precision.

The leisure industry additionally advantages from rotary level movement structures, using them to create dynamic and charming visible outcomes in the course of stay performances or filming. These systems add an additional size of excitement and aptitude to productions.

Moreover, inside the medical field, rotary degrees help in approaches like laser surgical procedure via supplying unique control over gear and gadgets. This stage of accuracy is critical while handling sensitive surgeries where precision is paramount.

Conclusion

A rotary level motion gadget is a powerful tool that gives precision and efficiency in diverse packages. By utilising one of a kind kinds of rotary stages, corporations can enhance their movement control capabilities and acquire excessive ranges of accuracy in their techniques. When selecting a rotary stage movement system, it is essential to recollect factors which include load capability, speed necessities, and compatibility with different system.

The versatility and reliability of rotary level movement structures make them crucial for industries ranging from production and electronics to analyze and improvement. With the capacity to maximise precision while preserving performance, those systems play a key position in using innovation and advancements throughout multiple sectors. Embracing the technology of rotary tiers opens up new possibilities for more suitable performance and productivity in diverse fields.