Conveyor System is automated equipment that is used in various industries for the purpose of mobility of goods, products, and raw materials from one place to another, mostly within the same zone or building. There are three key modules of a conveyor system: the belt support, the pulley, and the drive unit. Each constituent plays a special role, all systems consist of these parts although the design may differ. The belt support is one of the parts which ensures that the belt moves in a uniform manner, and if, in any case, the support unit is not stable, the belt slumps when an object is placed upon it. Similarly, the pulley system is an external factor that contributes to the control of bell movement, and in this element, each unit comprises of at least two pulleys, among which one is operated under the command and the other is futile. The drive unit permits the system to move with the help of counter demeanor that keeps the parts in a moving position, this unit of the conveyor system supports the belt to travel in reverse order and brings about repeated modifications in direction for some systems, and, however, some of the systems are physically operated.

It is considered a handy tool to deal with hefty goods, sharp articles, and raw supplies. The conveyor system is a competent conveyance system that provides steady movement not only of the company’s material but also transports the heavy-weighted items such as cars down to a production line, which makes it the most famous among the manufacturing industries and material handling and packaging businesses. In Thailand, the requirement for conveyor systems has increased due to environmental aspects. As there is an approach of low energy consumption along with low noise emission, the conveyor systems have gained massive market demand that guarantees customers satisfaction and astounding cost-effective operational outcomes.

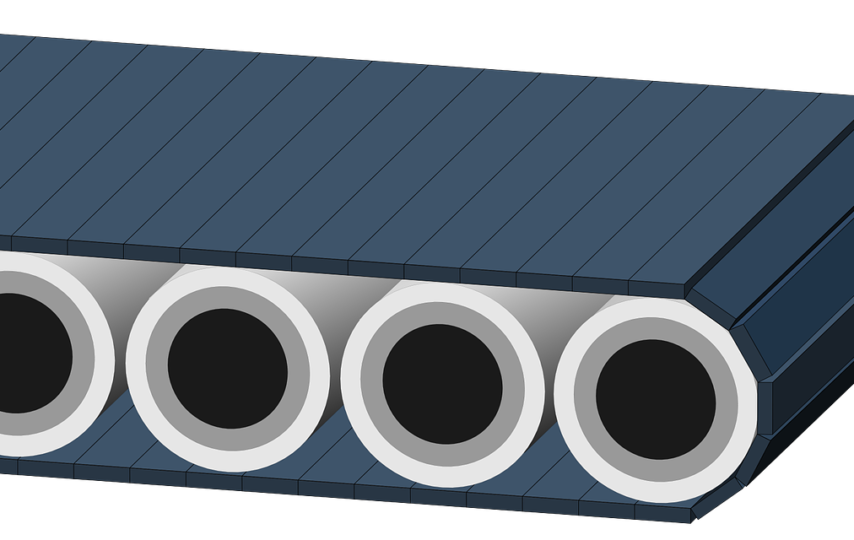

The conveyor system functions in the areas of mining, agriculture, food and beverage, warehouse and logistics, and automotive. It is also a consumer-friendly tool because it is helpful in driving people and food to the supermarkets, restaurants, hotels, and shopping centers with efficacy. There is a vast range of conveyors which can be used in a number of ways depending upon the need and requirement. There is a wide array of conveyor systems such as the Belt conveyor, Chain Driven Roller Conveyor, Bucket Conveyor, Chain Conveyor, Drag Conveyor, Aero-Mechanical Conveyor, Plastic Belt Conveyors, Spiral Conveyors, Gravity Conveyors, and a lot more.

Firstly, the conveyor system is extremely beneficial to use as it ensures the safe carriage of materials with the service of elevated conveyors. Secondly, it adds worth and increases the safety of the workplace as a result of automation and safeguards. Thirdly, it helps to meet individual preferences with the help of hydraulic, mechanical, and highly automated systems. Lastly, it aids to manage objects of different shapes, sizes, and weights reflecting time-effective excellence along with cost-saving solutions.

It is necessary to highlight that the conveying units are significant for business as it results in an increase to increased manufacturing in a properly organized way, which shows that such systems are the core elements of a firm. In order to assure high performance, there is a major need for accurate maintenance with regular supervision, inspection through trained staff. This portrays that right conveying system design is important to a great magnitude. In order to do the right selection of the conveyor system, this article will create better understanding of the prime components of operational safety, reliability, compliance, and productivity in terms of the total cost of ownership and energy to gain a competitive advantage in the market.

Source:jenbunjerd.com