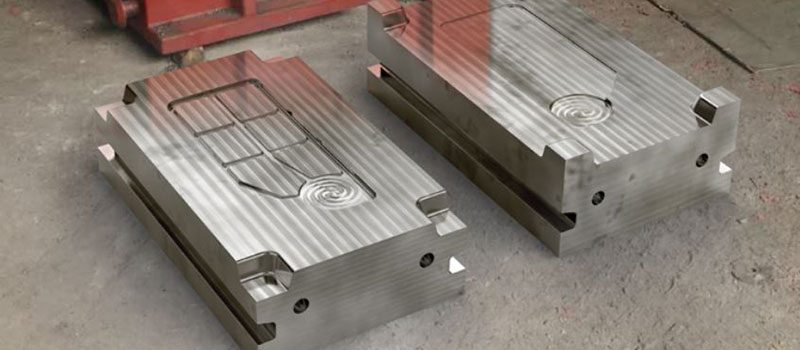

Rapid tooling is known as the process, which is used to test the product, that apply the MUD (Master United Die) to the mold base, which means many cavities and cores inserts share one same mold base. It is also called as the bridge, rapid or low volume molds. In this way, the cost of the mold base is more affordable and the lead time will be greatly reduced. For the tooling structure, we have different designs based on different quantities. For example, if you only have a few hundred manufacturing parts demand, we will design hand loading insert or use a post-machining tool instead of the complex tooling structure and machining.

Usually, the rapid tooling life is about 100000 shots for rapid tooling. It also depends upon the structure of the tooling. For sample structure tooling, the tooling life can be up to 500000 shots. When we compare the rapid mold with the traditional mold making, Rapid tooling can help you save 40% to 50% of the cost and 40% to 60% of the time. On t0p of that, some companies can provide DFM (design for manufacture) report to our customers to analyze product structure, tooling building feasibility, and potential quality risk. In this way, the tooling is safer. Our tooling lead time is about 10 to 25 calendar days based on different product and tool structures.

What metal materials are used for rapid tooling?

Aluminum is the best choice for simple geometry products and low volume production requirements, such as 5k to 10k quantity shots. By using aluminum the surface can be textured and polished to normal smoothness standard, but cannot meet the high glossy surface requests. The machining of the aluminum tool can be much faster because this material is softer and has better machinability. Besides, the machining cost will be reduced accordingly. Generally speaking, aluminum is the best metal material, the fastest and affordable way to make rapid tools.

P20 material is commonly used in rapid tooling. It is one of the most widely used tooling steels in the world. P20 works for a great majority of products dimension, surface finishing, and part geometry. Depending on different part sizes, molding resin, and tooling structure, the tooling life can be to 200k.

What is the advantage of rapid tooling?

Rapid tooling is an important step to testing the service and the product. This is a good way to confirm the product quality is better; this will helps to the customer’s satisfaction. Rapid tooling is used to reduce 40% to 50% cost compared with the traditional mold. It is also used to reduce 40% to 60% lead time compared with the traditional mold. The mold can be available for several surface finishes, such as texturing, polishing, sandblasting, and so on. Soft steel makes it easier to modify the tooling if the product design needs to be changed. The mold can be made as a family mold, so it can reduce the production lead time and keep the color consistency of the products. Rapid tooling is a good testing solution before a huge volume production mold.